Our Services

Our lab offers precision testing to help optimize feed performance, improve animal nutrition, and support efficient milling operations.

Particle Size Testing

Consistent grind size is critical to maximizing feed value and controlling processing costs.

Purpose of Particle Size Testing

Particle size testing estimates the average particle size in ground grain samples.

It also helps ensure consistent grind size for:

- Maximized feed efficiency

- Improved grinding efficiency

- Reduced costs

Available Testing Options

Currently offered for corn and complete feeds.

Why Does Particle Size Testing Matter?

Improved Nutrient Digestibility:

Proper particle size increases the surface area of the grain, making it easier for animals—especially monogastrics like pigs and poultry—to digest and absorb nutrients.

Feed Efficiency:

Achieving the right grind size (often referred to as the “sweet spot”) ensures animals get the most energy and nutrients from the feed, leading to better weight gain or production with less feed input.

Pellet Quality:

For pelleted feeds, uniform and appropriately sized particles contribute to better pellet durability and less fines, improving overall feed quality and reducing waste.

Reduced Feed Wastage:

Inconsistently ground feed can lead to sorting by animals and increased feed losses, particularly in dry feeding systems.

Animal Health:

Very fine particles can lead to gastric ulcers in pigs or respiratory issues due to dust, while too coarse particles may reduce digestibility or cause selective feeding.

Grinding Efficiency:

Overgrinding increases energy use and wear on equipment. Particle size testing helps balance grinding precision with cost-effective mill operation.

Consistency and Quality Control:

Routine particle size testing ensures batches are consistent, supporting predictable animal performance and maintaining feed mill quality standards.

Testing Methodology

We use an industry-standard 13-sieve method as outlined in ASAE S319.5 and include a sieving agent.

Benefits of Using a Sieve Agent

- Reduces static electricity and friction during testing.

- Promotes even distribution of particles across sieves.

- Results in more accurate and repeatable particle size measurements.

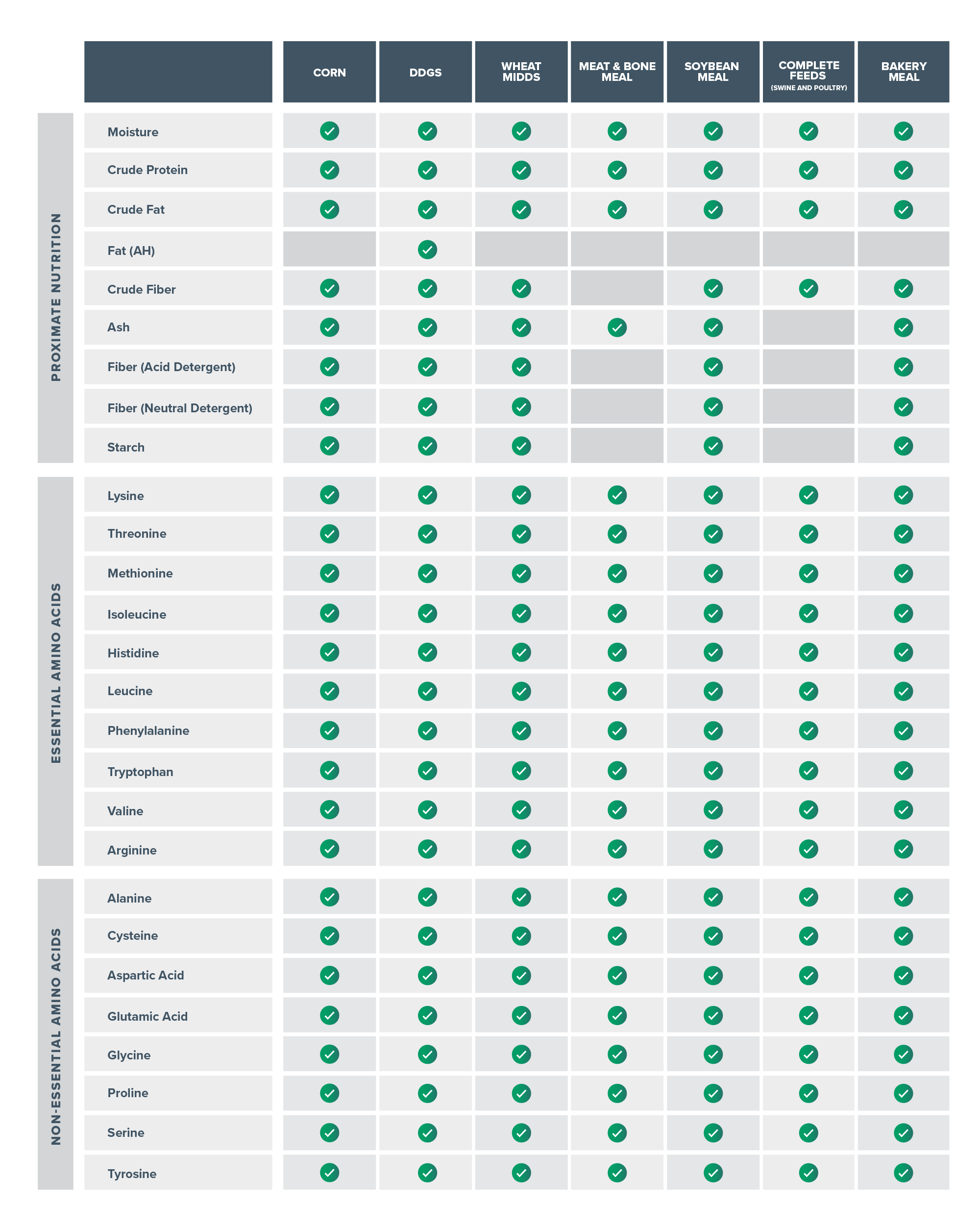

Ingredient & Complete Feed Testing

Get a complete nutritional profile for quality control & process verification.

Why It Matters

Complete feed testing verifies that the feed meets nutritional specifications and ensures process consistency.

Testing Approach

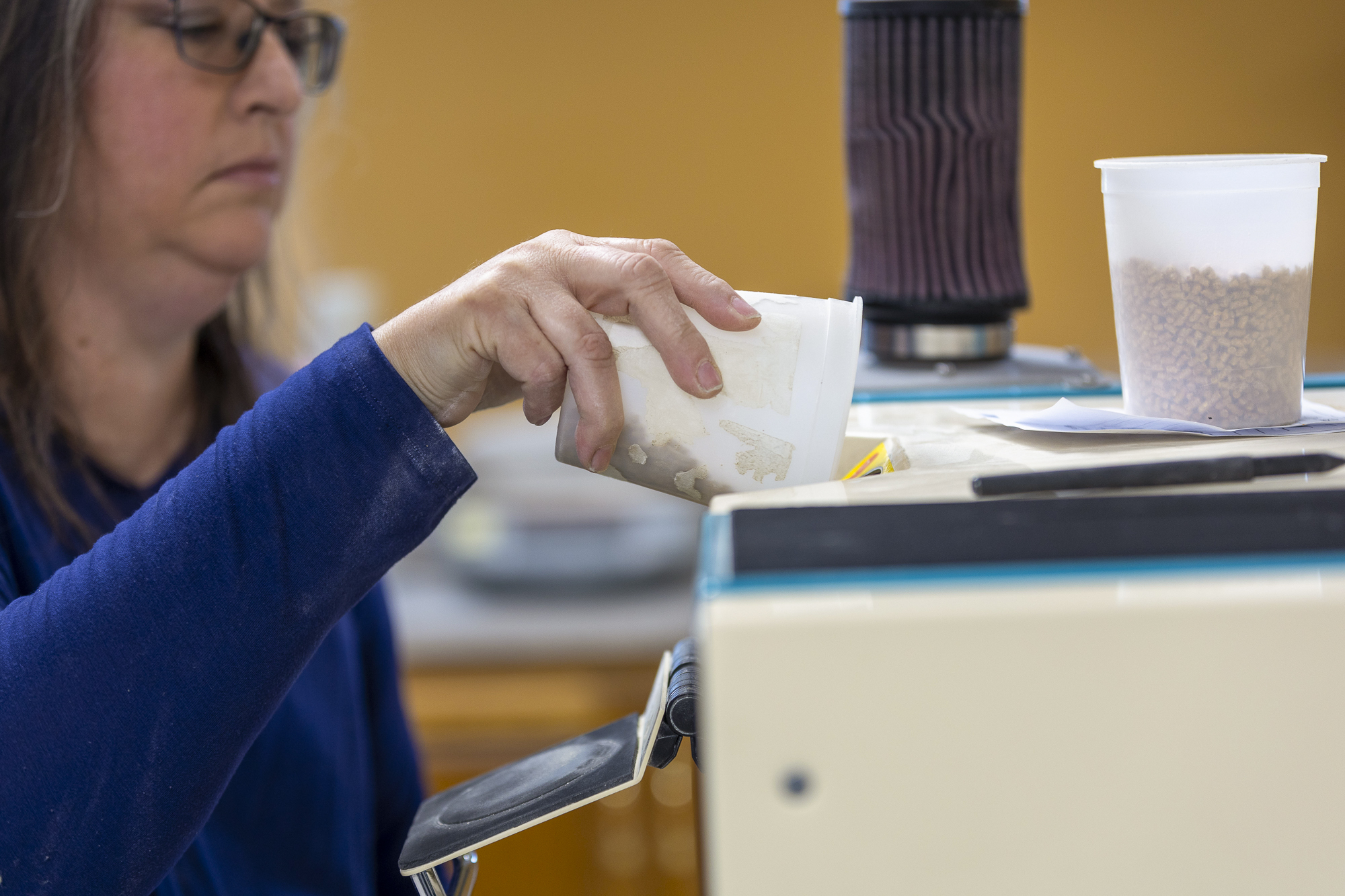

We use NIR (Near-Infrared) analysis for rapid, non-destructive testing.

Every sample includes:

- Proximate nutrient predictions

- Amino acid profile predictions

Process Monitoring

Clients have access to an online database to:

- Track historical results

- Chart trends over time

- Detect process shifts or ingredient variation early

What is NIR analysis?

Check out our NIR Analysis page.

Pellet Quality Testing

Whole pellets mean better nutrition delivery and more consistent intake.

Purpose of Pellet Quality Testing

- Ensures animals receive the maximum number of whole pellets, improving nutrient absorption and feed conversion rates

- Helps monitor equipment performance and process conditions in the feed mill

Testing Equipment and Method

Pellet quality testing is traditionally done with a tumbler machine to measure pellet durability.

We use the Holmen NHP200, a faster and more consistent method for evaluating pellet quality. The process includes:

- Measuring initial fines in the sample

- Using air pressure agitation via the Holmen system for a set time

- Measuring the remaining whole pellets after agitation

Test Results Provided

- Percent Initial Fines

- Percent Durability

- Estimated Percent of Pellets Delivered to the Animal

Benefits

- Quick and cost-effective

- Provides actionable data to optimize pellet quality and improve milling efficiency

Mycotoxin Testing

Protect your livestock – and your market value.

What are mycotoxins?

- Mycotoxins are toxic compounds produced by mold that can contaminate crops like corn, wheat, and DDGs.

- Mycotoxins can form before or after harvest, during storage, transport, or processing.

- They are not destroyed by cooking or freezing – making testing essential.

Testing New Crop Corn

- Important for marketing strategy—tolerance levels vary widely by end user (e.g., feed mills, ethanol plants, elevators).

- Pre-testing saves time and helps plan deliveries more effectively.

Routine Mycotoxin Testing of Mill Ingredients

Rapid and cost- effective screen available for:

- Corn

- DDGs (Distillers Dried Grains)

- Wheat Midds